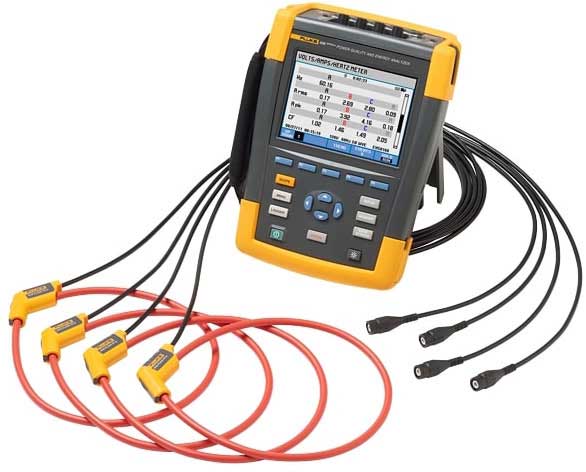

Model: 435-II | Order No: 435-II Series

The Power Quality analyzers that can monetize the cost of energy waste due to poor power quality. More powerful sampling options, greater accuracy and larger memory makes the Fluke 435-II better for longer term, higher resolution or more demanding power quality studies. The wide range of measurement functions and measurement methods make it the perfect tool for both power quality troubleshooting and discovering energy savings. Whether you’re checking the performance of motors and generators, trying to discover the source of an intermittent power problem or performing an energy study…this tool gives you the data you need to quickly get to the source of the problem.

Discontinued!

This product has been discontinued and is no longer available.

There is no direct replacement, however we recommend the:

Not what you're looking for? Let’s do a search and help you find what you need.

| Model | Measurement range | Resolution | Accuracy | |

| Volt | ||||

| Vrms (ac+dc) | 435-II | 1 V to 1000 V phase to neutral | 0.01 V | ± 0.1% of nominal voltage**** |

| Vpk | 1 Vpk to 1400 Vpk | 1 V | 5% of nominal voltage | |

| Voltage Crest Factor (CF) | 1.0 > 2.8 | 0.01 | ± 5 % | |

| Vrms½ | 435-II | 0.1 V | ± 0.2% of nominal voltage | |

| Vfund | 435-II | 0.1 V | ± 0.1% of nominal voltage | |

| Amps (accuracy excluding clamp accuracy) | ||||

| Amps (ac +dc) | i430-Flex 1x | 5 A to 6000 A | 1 A | ± 0.5% ± 5 counts |

| i430-Flex 10x | 0.5 A to 600 A | 0.1 A | ± 0.5% ± 5 counts | |

| 1mV/A 1x | 5 A to 2000 A | 1A | ± 0.5% ± 5 counts | |

| 1mV/A 10x | 0.5 A A to 200 A (ac only) | 0.1 A | ± 0.5% ± 5 counts | |

| Apk | i430-Flex | 8400 Apk | 1 Arms | ± 5 % |

| 1mV/A | 5500 Apk | 1 Arms | ± 5 % | |

| A Crest Factor (CF) | 1 to 10 | 0.01 | ± 5 % | |

| Amps½ | i430-Flex 1x | 5 A to 6000 A | 1 A | ± 1% ± 10 counts |

| i430-Flex 10x | 0.5 A to 600 A | 0.1 A | ± 1% ± 10 counts | |

| 1mV/A 1x | 5 A to 2000 A | 1A | ± 1% ± 10 counts | |

| 1mV/A 10x | 0.5 A A to 200 A (ac only) | 0.1 A | ± 1% ± 10 counts | |

| Afund | i430-Flex 1x | 5 A to 6000 A | 1 A | ± 0.5% ± 5 counts |

| i430-Flex 10x | 0.5 A to 600 A | 0.1 A | ± 0.5% ± 5 counts | |

| 1mV/A 1x | 5 A to 2000 A | 1A | ± 0.5% ± 5 counts | |

| 1mV/A 10x | 0.5 A A to 200 A (ac only) | 0.1 A | ± 0.5% ± 5 counts | |

| Hz | ||||

| Hz | Fluke 435 @ 50 Hz nominal | 42.500 Hz to 57.500 Hz | 0.001 Hz | ± 0.01 Hz |

| Fluke 435 @ 60 Hz nominal | 51.000 Hz to 69.000 Hz | 0.001 Hz | ± 0.01 Hz |

|

| Power | ||||

| Watts (VA, var) | i430-Flex | max 6000 MW | 0.1 W to 1 MW | ± 1% ± 10 counts |

| 1 mV/A | max 2000 MW | 0.1 W to 1 MW | ± 1% ± 10 counts | |

| Power factor (Cos j/DPF) | 0 to 1 | 0.001 | ± 0.1% @ nominal load conditions | |

| Energy | ||||

| kWh (kVAh, kvarh) | i430-Flex 10x | Depends on clamp scaling and V nominal | ± 1% ± 10 counts | |

| Energy loss | i430-Flex 10x | Depends on clamp scaling and V nominal | ± 1% ± 10 counts Excluding line resistance accuracy | |

| Harmonics | ||||

| Harmonic order (n) | Harmonic order (n) | DC, 1 to 50 Grouping: Harmonic groups according to IEC 61000-4-7 | ||

| Inter-harmonic order (n) | Inter-harmonic order (n) | OFF, 1 to 50 Grouping: Harmonic and Interharmonic subgroups according to IEC 61000-4-7 | ||

| Volts | %f | 0.0 % to 100 % | 0.1 % | ± 0.1% ± n x 0.1 % |

| %r | 0.0 % to 100 % | 0.1 % | ± 0.1% ± n x 0.4 % | |

| Absolute | 0.0 to 1000 V | 0.1 V | ± 5% * | |

| THD | 0.0 % to 100 % | 0.1 % | ± 2.5 % | |

| Amps | %f | 0.0 % to 100 % | 0.1 % | ± 0.1% ± n x 0.1% |

| %r | 0.0 % to 100 % | 0.1 % | ± 0.1% ± n x 0.4 % | |

| Absolute | 0.0 to 600 A | 0.1 A | ± 5% ± 5 counts | |

| THD | 0.0 % to 100 % | 0.1 % | ± 2.5 % | |

| Watts | %f or %r | 0.0 % to 100 % | 0.1 % | ± n x 2% |

| Absolute | Depends on clamp scaling and V nominal | - | ± 5% ± n x 2 % ± 10 counts | |

| THD | 0.0 % to 100 % | 0.1 % | ± 5 % | |

| Phase Angle | -360° to +0° | 1° | ± n x 1° | |

| Flicker | ||||

| Plt, Pst, Pst(1min) Pinst | 0.00 to 20.00 | 0.01 | ± 5 % | |

| Unbalance | ||||

| Volts | % | 0.0 % to 20.0 % | 0.1 % | ± 0.1 % |

| Amps | % | 0.0 % to 20.0 % | 0.1% | ± 1 % |

| Mains signaling | ||||

| Threshold levels | Threshold, limits and signaling duration is programable for two signaling frequencies | - | - | |

| Signaling frequency | 60 Hz to 3000 Hz | 0.1 Hz | ||

| Relative V% | 0 % to 100 % | 0.10 % | ± 0.4 % | |

| Absolute V3s (3 second avg.) | 0.0 V to 1000 V | 0.1 V | ± 5 % of nominal voltage | |

| General specifications | ||||

| Case | Design Rugged, shock proof with integrated protective holster Drip and dust proof IP51 according to IEC60529 when used in tilt stand position Shock and vibration Shock 30 g, vibration: 3 g sinusoid, random 0.03 g 2 /Hz according to MIL-PRF-28800F Class 2 | |||

| Display | Brightness: 200 cd/m 2 typ. using power adapter, 90 cd/m 2 typical using battery power Size: 127 mm x 88 mm (153 mm/6.0 in diagonal) LCD Resolution: 320 x 240 pixels Contrast and brightness: user-adjustable, temperature compensated | |||

| Memory | 8GB SD card (SDHC compliant, FAT32 formatted) standard, upto 32GB optionally Screen save and multiple data memories for storing data including recordings (dependent on memory size) | |||

| Real-time clock | Time and date stamp for Trend mode, Transient display, System Monitor and event capture | |||

| Environmental | ||||

| Operating temperature | 0 °C ~ +40 °C; +40 °C ~ +50 °C excl. battery | |||

| Storage temperature | -20 °C ~ +60 °C | |||

| Humidity | +10 °C ~ +30 °C: 95% RH non-condensing +30 °C ~ +40 °C: 75% RH non-condensing +40 °C ~ +50 °C: 45% RH non-condensing | |||

| Maximum operating altitude | Up to 2,000 m (6666 ft) for CAT IV 600 V, CAT III 1000 V Up to 3,000 m (10,000 ft) for CAT III 600 V, CAT II 1000 V Maximum storage altitude 12 km (40,000 ft) | |||

| Electro-Magnetic-Compatibility (EMC) | EN 61326 (2005-12) for emission and immunity | |||

| Interfaces | mini-USB-B, Isolated USB port for PC connectivity SD card slot accessible behind instrument battery | |||

| Warranty | Three years (parts and labor) on main instrument, one year on accessories | |||

Click on a category to view a selection of compatible accessories with the Fluke 435-II Series of Power Quality Analyzers.